The Success of Metal Fabricators: A Comprehensive Guide

Introduction

Welcome to a comprehensive guide on the world of metal fabrication and the invaluable services provided by expert metal fabricators. In this article, you will uncover the secrets to their success and understand the significance of bandsaw machine repair in ensuring uninterrupted operations.

What Are Metal Fabricators?

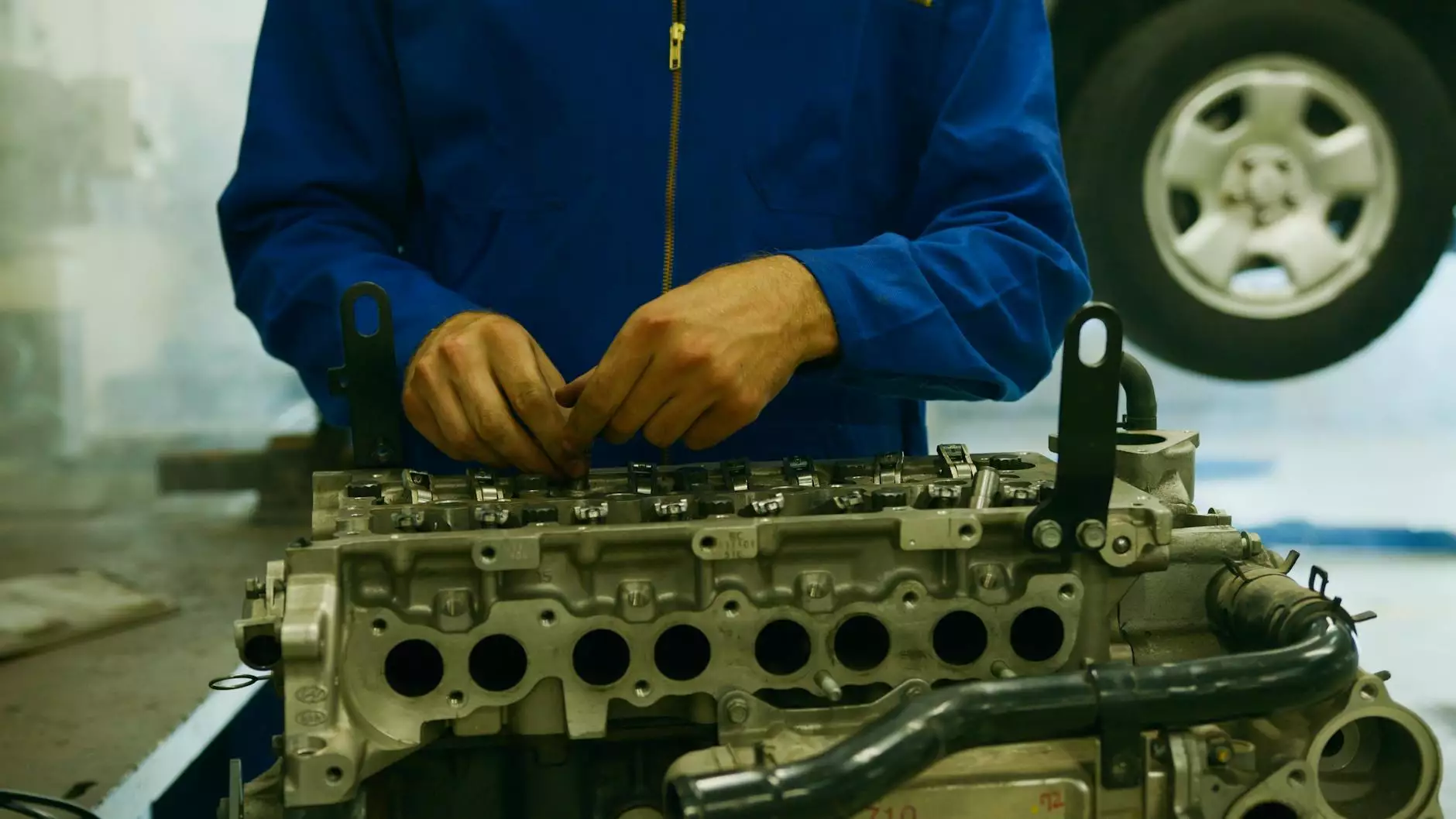

Metal fabricators are skilled professionals who specialize in transforming raw metal materials into valuable products and components. Whether it's custom metal fabrication or large-scale industrial projects, metal fabricators play a crucial role in various sectors, including construction, automotive, aerospace, and more. They possess the expertise and knowledge required to handle a wide range of metals, such as steel, aluminum, brass, and copper.

The Importance of Metal Fabrication

Metal fabrication is integral to the success of multiple industries. The ability to shape, cut, weld, and assemble metals allows businesses to create unique and functional products tailored to their specific requirements. Metal fabricators bring ideas to life, collaborating with engineers, architects, and designers to turn concepts into reality. Whether it's constructing bridges, manufacturing machinery, or creating custom architectural elements, the precision and craftsmanship of metal fabrication ensure the highest quality finished products.

Understanding Bandsaw Machine Repair

Among the various tools utilized by metal fabricators, bandsaw machines play a crucial role. Bandsaw machines are used for precise cutting and shaping of metal materials, allowing fabricators to create complex designs and ensure accurate measurements. However, like any machinery, bandsaw machines require regular maintenance and repair to operate optimally.

The Significance of Bandsaw Machine Repair

Effective bandsaw machine repair is essential for the continuous operation of metal fabrication businesses. A malfunctioning or poorly maintained bandsaw machine can lead to delays, increased production costs, and compromised product quality. By prioritizing bandsaw machine repair, metal fabricators can avoid downtime and ensure seamless production.

The Benefits of Professional Bandsaw Machine Repair

Investing in professional bandsaw machine repair services offers numerous advantages for metal fabricators:

1. Minimized Downtime

Experienced bandsaw machine repair technicians understand the urgency of fixing issues promptly. They have the expertise to diagnose problems efficiently and provide effective solutions, minimizing downtime and preventing significant disruptions to production schedules.

2. Enhanced Safety

Well-maintained bandsaw machines significantly reduce the risk of accidents or injuries in the workplace. Skilled repair professionals ensure that all safety features are in place and functioning correctly, creating a secure working environment for metal fabricators.

3. Cost Savings

Timely bandsaw machine repairs can save money in the long run by preventing costly breakdowns or extensive damage. By identifying and resolving potential issues early on, metal fabricators can avoid expensive repairs or the need for complete machine replacements.

4. Improved Efficiency

When bandsaw machines are operating at their best, the efficiency of metal fabrication processes increases. Regular maintenance and repair ensure smooth operation, accurate cuts, and precise measurements, leading to higher productivity and customer satisfaction.

Conclusion

Metal fabricators play a significant role in shaping the world around us. Their dedication to precision, creativity, and innovation allows for the creation of remarkable products. Bandsaw machine repair is an integral part of ensuring seamless production and operational excellence. By partnering with reliable professionals and prioritizing repair and maintenance, metal fabricators can surpass expectations, deliver exceptional results, and dominate the industry.